Screen Printing Benefits and Info

Screen printing has long been a standard for custom shirt creation and provides the benefit of low costs on large custom ink print runs. Screen printing is the process of pressing ink through a mesh that is created to block all of the areas other than where you want the design. With this process, a separate screen is used for each color of your design. Screen printing is great for projects where the design has only one or a small number of colors. Our unique method of screen printing allows us to create your shirts without the traditional setup fees associated with this process. Traditionally, a separate setup fee is charged for each color in your design. This can make small runs costly. While our method does not incur setup fees, screen printing is still much more cost effective the larger the quantity of shirts that you order. Screen printing colors are crisp and vibrant, and work best on materials that are 100% cotton up to a 50/50 blend of cotton and polyester. We also have inks that are designed for 100% polyester performance fabrics.

- Great for medium to large runs

- Crisp colors

- Works on most fabrics

- No Setup fees

Embroidered Shirts, Hats, and Apparel

Embroidery is a long lasting and affordable option for small to medium jobs with small designs. Embroidery can be done on most materials, and can be washed over and over without ink wearing out. Custom embroidered shirts are usually preferred for more professional applications like polo shirts and dress shirts for trade shows, and can also be used on water resistant fabrics like Carhartt Rain Defender® or nylon windbreakers where other customization options have adhesion problems. Embroidery is not typically the best option for custom apparel that has large designs as it becomes costly for items like sweatshirts with large images on the back, but we do offer this service for those who want the durability of embroidery and are less concerned about cost.

- Great for corporate professional apparel

- Durable and long-lasting

- Available for most materials

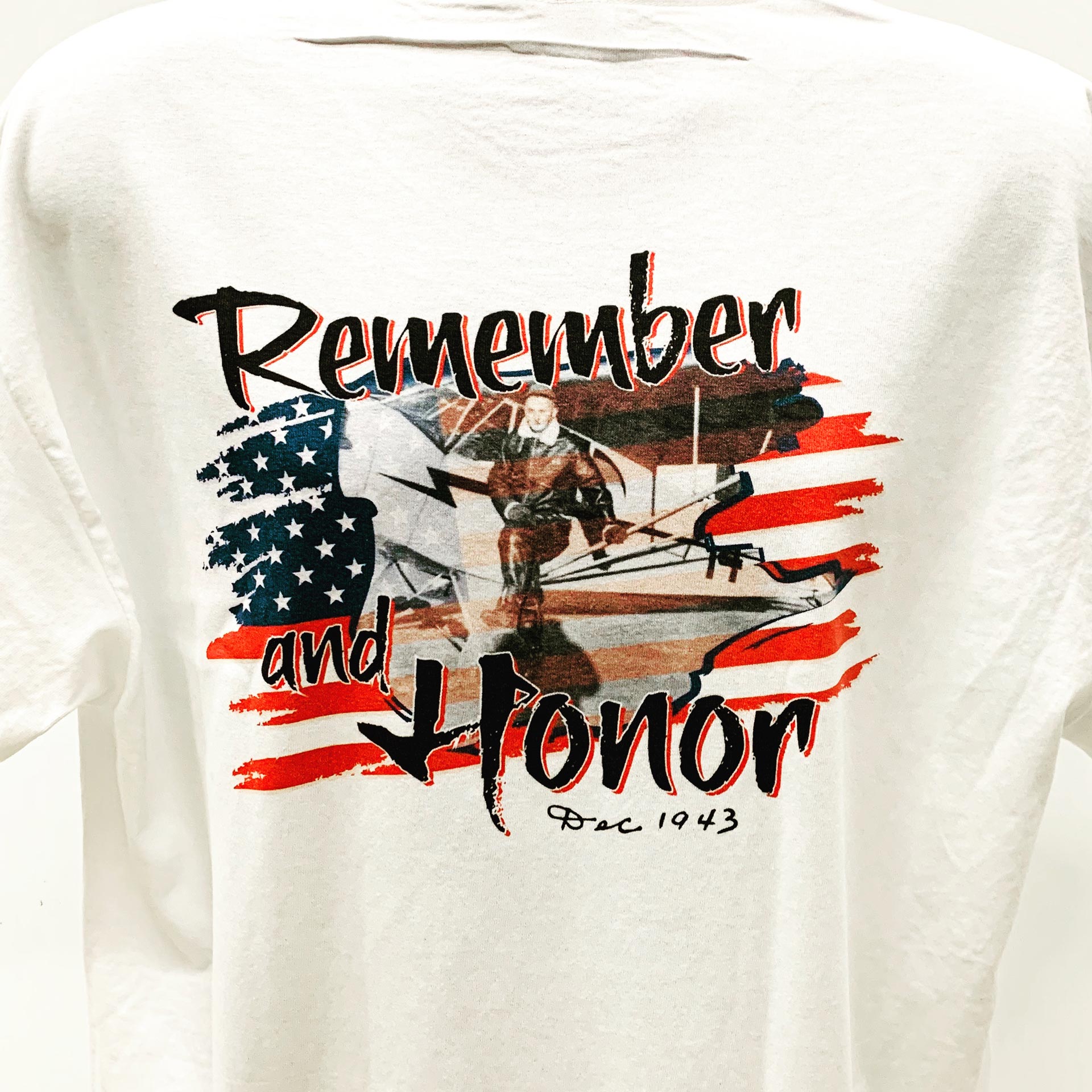

Direct to Garment Printing

Direct to garment (DTG) printing can reproduce complicated images accurately on something as soft as a shirt or sweater, or even on items like wood and bar coasters. Unlike Screen printing and embroidery, Direct to garment printing can print as many colors as you like with no additional costs or setup fees. From a single color design to full-color photographs, this process allows for endless customization options at a reasonable cost for small to medium jobs.

DTG ink binds directly to the fibers of the material. After printing, heat is applied to bond the ink to the material. The entire printing process can take as little as a few minutes per shirt. Direct to garment printing can render millions of colors and requires no setup fees or per color charges. With DTG you simply put the shirt in the printer and it prints on the design similar to ink on paper, this makes it time efficient and promotes accuracy with image placement. Like screen printing, this process requires shirts to be at least 50% cotton in order to work well and allow the inks to properly bond to the fibers of the shirt. For dark color shirts, a more involved process is needed in order to ensure the colors of your shirt stand out. For dark shirts, we will use a pre-treating process, then print the background of your design in white ink, and finally print the colors on your shirts. This process increases the cost for dark colored shirts as it requires more ink and labor, but still produces quality shirts at a reasonable cost for small and medium sized orders.

- No set-up fees

- Full color spectrum printing

- Durable and long lasting

- Soft feel like it’s part of the fabric

- Low cost for small to medium quantities

- Quick turn-around times

Heat Transfer Customization

Heat transfer graphics offer additional options for customizing a shirt or apparel design. Full-color graphics can be printed on special vinyl application material and transferred to shirts, table cloths, or even sails. These graphic applications are durable and look great. Heat transfers can be done on most materials including synthetic fibers that cannot be screen printed or DTG printed. In addition to the eye-catching vibrance of heat transfer graphics, shirts and other fabrics can be customized using graphics with specialty finishes like glitter. Pink glitter tends to be a fan-favorite. The heat transfer process starts with printing and/or cutting your design using our professional grade printer. This allows full spectrum printing, vibrant colors and intricate cutting for letters and detailed graphics. Once the design has been printed and cut, we apply the graphics to your shirt or other material using a commercial heat press. Like our direct to garment process, there are no setup fees and it is cost effective for small to medium quantities.

- No set-up fees

- Vibrant full color graphics

- Durable and long lasting

- Specialty finishes like glitter

- Low cost for small to medium quantities

- Quick turn-around times

Custom Designed Apparel

Trade shows, Pee Wee basketball leagues, marathons, family vacations, businesses and more all have one thing in common, custom t-shirts. Our design team will work with you to create the design you want, or you can provide a design ready-to-print. We’ll work with you to choose the right process and deliver you finished products that you can’t wait to wear.

Get a Quote

According to Forbes, you have roughly seven seconds to make a good impression upon meeting someone for the first time. With this in mind, it is absolutely crucial to make sure you come off as professional, talented, and knowledgeable all within that extremely short time frame. Besides the age-old tropes of using a solid handshake, dressing the part, and properly preparing, the business materials you use can help you stand apart from the crowd.